Log

- September 12, 2020, Open Up Summit global | → Video Recording available here & below ↓

Link

opencircularity.info/open-up

[ o°]

*

*

Hello,

I am Lars Zimmermann – designer, artist and activist from Berlin Germany. I cofounded a global project on open source circular economy called “Open Source Circular Economy Days”, I run a design studio for open circular design and environmental activism called Mifactori. And I work often in education for example as a guest professor for sustainable open design at universities.

–

Sustainability

And there I said it already: I am interested in Open Source Hardware – as a means to make sustainable products and enable sustainable practices around them.

–

–

Usually at this point I explain Open Source Hardware. But I think in this context I don’t need to spend much time on this. Open Source Hardware is Open Source for physical objects. You make hardware designs publicly available so that anyone can study, modify, distribute, make, and sell the design or hardware based on that design. People do this in – many – different – shapes & forms.

But why is Open Source Hardware a great means to sustainability? Sustainability is about products that support:

→ repair

→ reuse

→ refurbishment

→ recycling

→ surviving climate change

–

So: Sustainability is about enabling different practices around products than throwing them in the trash. More productive things done by more people. And this is exactly what Open Source is about! Enabling more people to do more productive things with stuff. The core of “closed source” is to block all kinds of activities, so closed source makes sustainability hard.

Right? Yes, on an abstract meta level the combination makes sense, a perfect couple made, made for each other. But I am a designer, artist and maker who likes theory, but is mainly interested in reality. So let’s test this assumption. First step a fictional story about a motorcycle. An open source motorcycle is theoretically easy to:

repair ?

Open design files help to fix things. When parts and solutions follow accessible standards and are simple – fixing is easy.

reuse ?

When I can see in the design files or construction itself how parts need to be placed and work with other parts – it is easier to reuse them in other designs.

refurbishment ?

When the design is open it is easier to order, replace, or manufacture missing and broken parts.

recycling ?

If I can see in the design files what materials are used and how they are assembled – recycling becomes easier.

surviving climate change ?

Which city is smarter? The “smart city” with street lights that are technically sophisticated and networked? Or the city with open documented, accessible, easy to understand street lights? When a storm hits the city infrastructure – which lamps are easier to repair locally? When the coastline moves – which lamps are easier to dismantle, take away and put up in another region? Openness helps us to adapt!

…

Made to work as Open Source

OK. Our idea has passed the first test.

But if you have listened carefully you might have noticed that these stories already brought up more things to consider. Sustainable hardware needs to be designed differently to enable sustainable practices. And the same is true for Open Hardware. Open Source Hardware needs to be designed differently to enable Open Source practices.

The difference between software and hardware is striking. Computers are the same everywhere in the world. The same basic general purpose machine. So you can download Open Source Software from everywhere and start using it within minutes on your local machine. The computer it runs on is already built. With hardware it is different. You can only download the design files for a tractor. But the difficult and expensive part of sourcing parts and materials and putting them together is still ahead of you.

This is how software works, but not hardware.

Open Hardware must make an effort to make things easy to build on site. (This is why digital fabrication tools like 3D printing, laser cutting and CNC milling are such a big thing in open hardware – but we can’t make everything with these tools). Here is what the open hardware definition states in its first paragraph about this:

.

→ This is a straight up suggestion how to make your design in order to make it easier to actually physically reproduce somewhere else.

It means that a lot of common design practices and ideas become problematic. Open Source Hardware can’t just be about sharing design files under open licenses – at least if you want to make it work for global collaboration.. You need to design it for this too.

Rebrand: Open (Circular) Design

I was part of a global project called the “Open Source Circular Economy Days”. From 2015 to 2018 we asked people – designers, makers, engineers, consultants and more – to start globally connected the development of open source circular solutions. The project got a lot of excitement in the beginning. Groups in more than 100 cities across the globe signed up to do local events(→ 2015, → 2016). But then the project got stuck.

One of the reasons for this we found out through a questionnaire: A lot of people were interested in the project were turned off by the word “Open Source”. It sounded to them like something very complex and technical – something made for an elite exclusive “in group” of tech wizards they don’t felt to be part of. They could not grasp it no matter how much effort we made to explain it and to teach how to make business with it. Although the core ideas are so simple and supported by these people.

So what I learned from that is that “Open Source” might not be the best wording to get groups like Designers and related professions into making actual “Open Source designs”. So at Mifactori we switched and use “Open Design” or “Open Circular Design” in our campaign, education and design work.

=

→ Article: What Is Open (Circular) Design

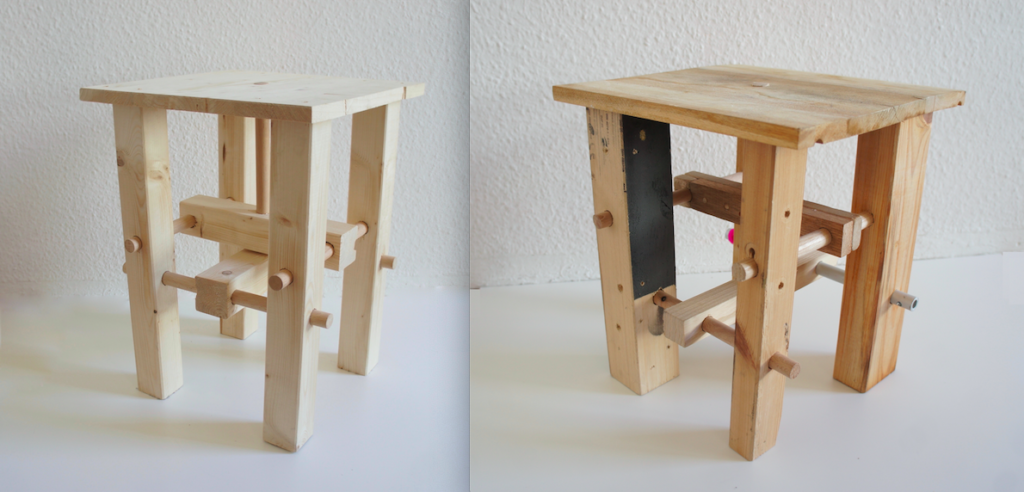

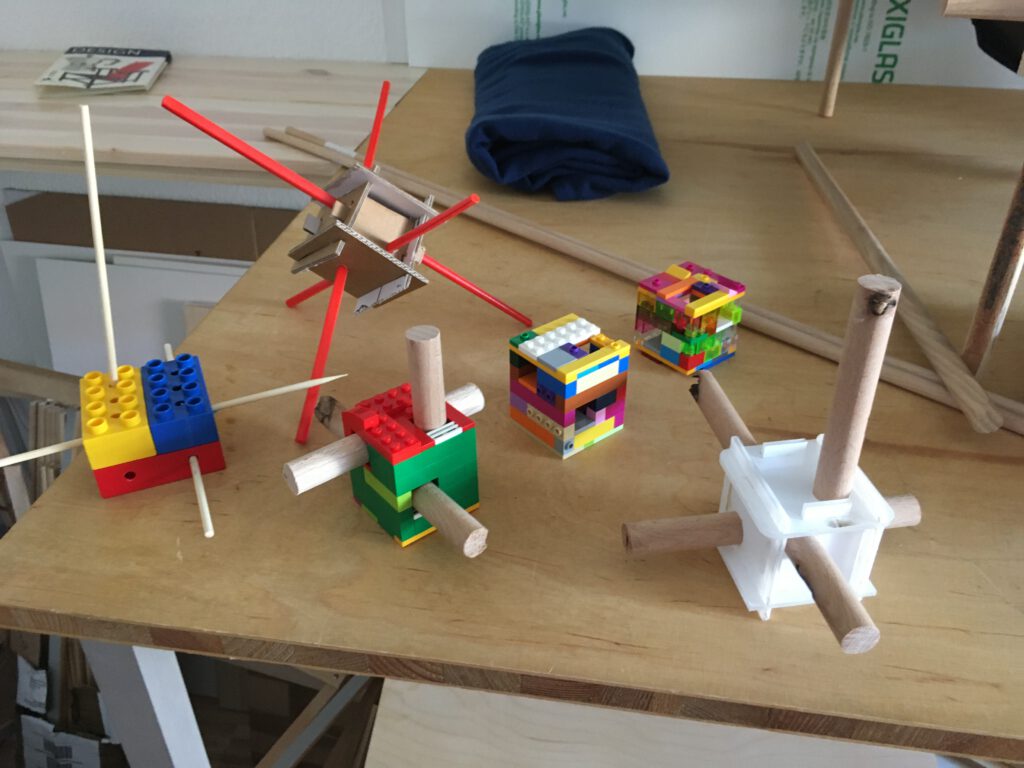

I am sitting here in the Mifactori workshop. I am surrounded by prototypes for open (source) circular designs. We are going to publish them over the course of the next months. Here are a few pics from the development stage:

–

(Some are already on our page → Ringbein.)

*

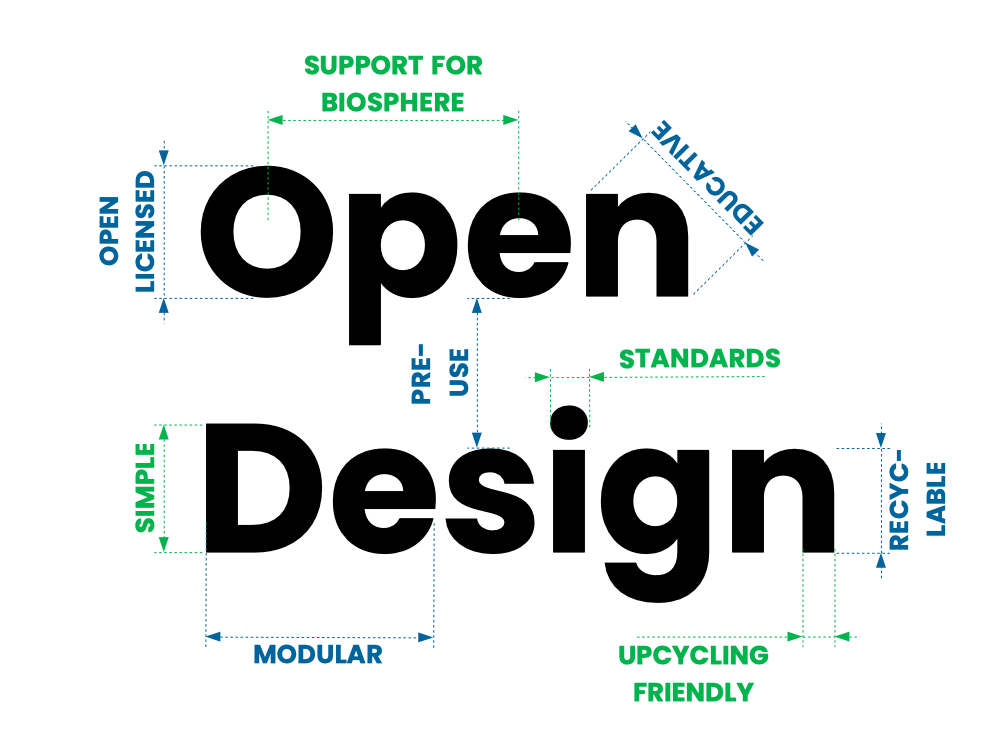

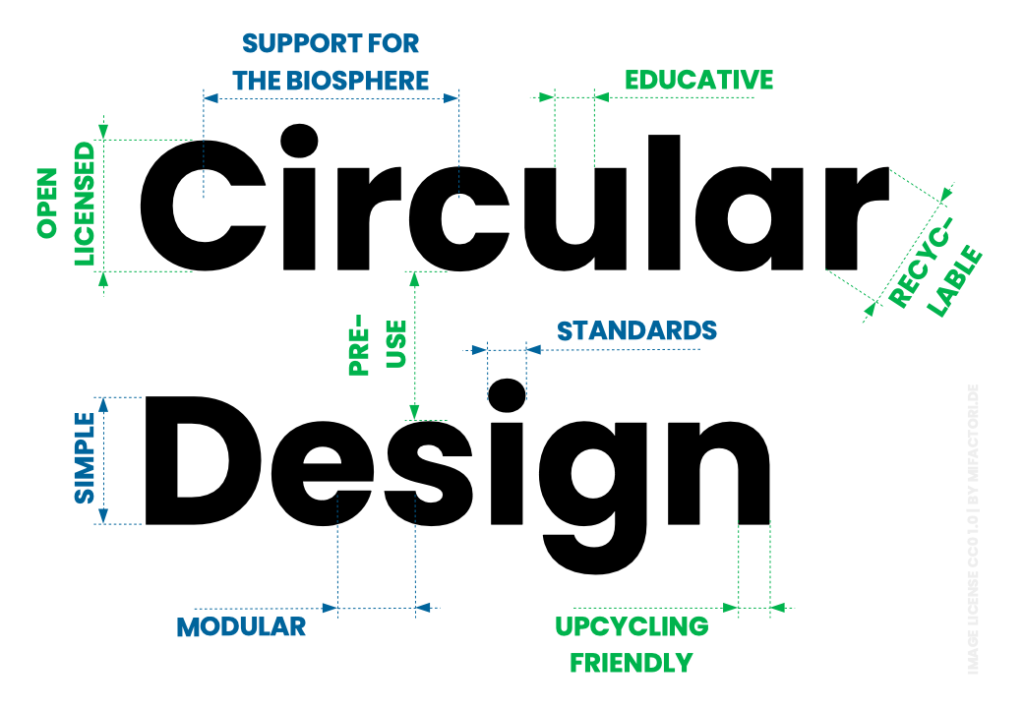

OK. Let’s jump → into the article explaining the methodologies of “Open Circular Design”. The key is that we set a new frame:

“Open means to leave options open for the future. Enable and keep as many different productive futures as possible; with design, through design and despite of design.”

Open for interaction, open for change, open to make it, open to…

–

And from there we describe 9 methodologies for Open Circular Design that all support Open Source Hardware or are direct copies of Open Source Hardware methodologies!

Let’s have a quick look, what are these methodologies and how do they support Open Source Hardware practices? If you are on this page right now you can scroll up to the pictures of our designs ↑ to compare to what you hear.

Simple → Things that are simple to understand and make are open to more people. You get closer to “everyone”.

Educative → Designs that teach core design concepts in whatever way enable more people to work with hardware designs.

Standards → Standard parts are often easier to source and support mutual understanding and collaboration.

Modular → Modularity enables reuse of parts and that helps with sourcing of parts and modification of designs.

Recyclable → Recycling is a longterm game of sourcing parts and materials. Sometimes recycling can even be done by you already.

Upcycling Friendly → Designs that make it easy to incorporate already used parts or stuff from the trash make sourcing parts easier.

Pre-Use → Pre-Use is a technique to creatively repurpose and therefore source parts you already have. But you leave them intact so they can still full fill their initial purpose – in case you need to source for that again.

Open Licensed → Of course don’t put any legal barriers between the design and other people that want to work with it. Especially don’t make any weird and horrible moves with Creative Commons licenses for your hardware (pls. read FAQ: Why are Creative Commons ”Non Commercial” licenses not Open Source and a big problem for hardware & product design)

*

OK. I think it became clear Mifactori is not just a studio for open source circular products and interiors. We are also in campaigning and education. I teach sometimes as a guest professor at universities and over the years we became convinced that sustainable design needs to think about activism – you can’t separate both worlds.

Summary / Take Away

Open Source Hardware faces the same problems as sustainability. How to design products that are quick and easy to make and change. If we bring these two worlds together they can inform each other in order to make progress in both of them.

Bye

More from us and future updates

Sign up to our Newsletter → Newsletter SignUp

Or follow Mifactori on social media: Twitter, Instagram, Facebook, LinkedIn, Flickr, Tumblr

Or just browse the many resources on our page mifactori.de

–

And one more time the link to this page

opencircularity.info/open-up

[ o°]